-

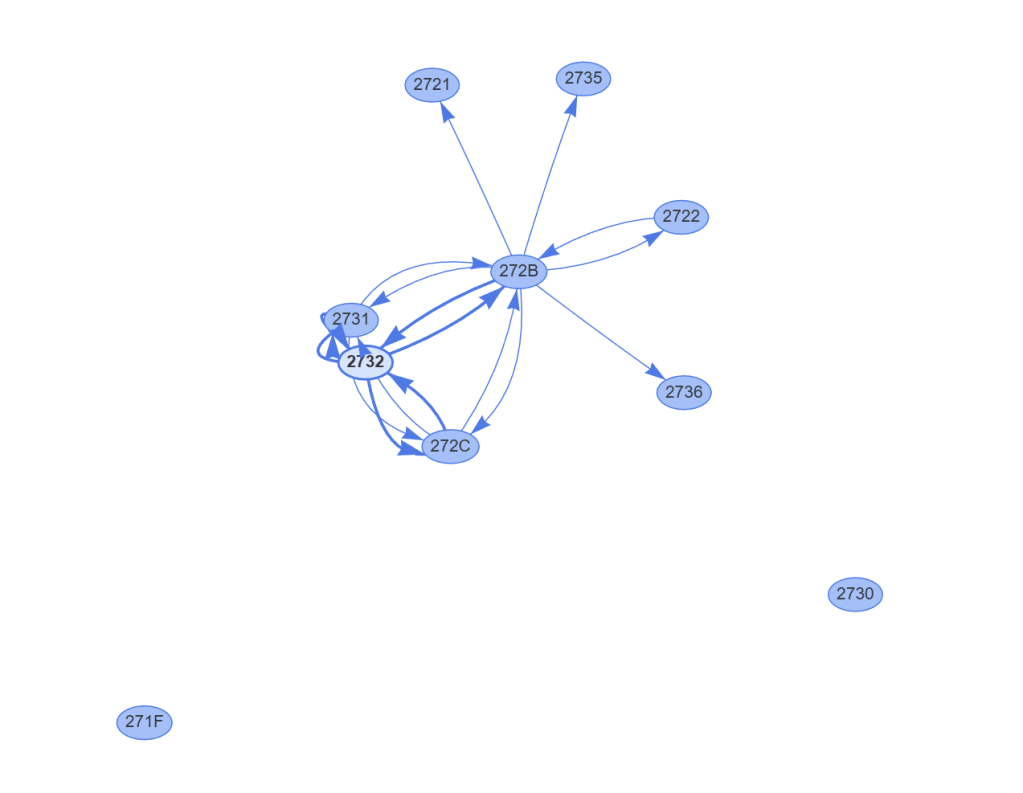

Trying to fix the Thread Network for my Matter Temperature Sensor

In this post, I look at my Thread network and diagnose why my Temperature Sensors keep losing connection. Read ⇢

-

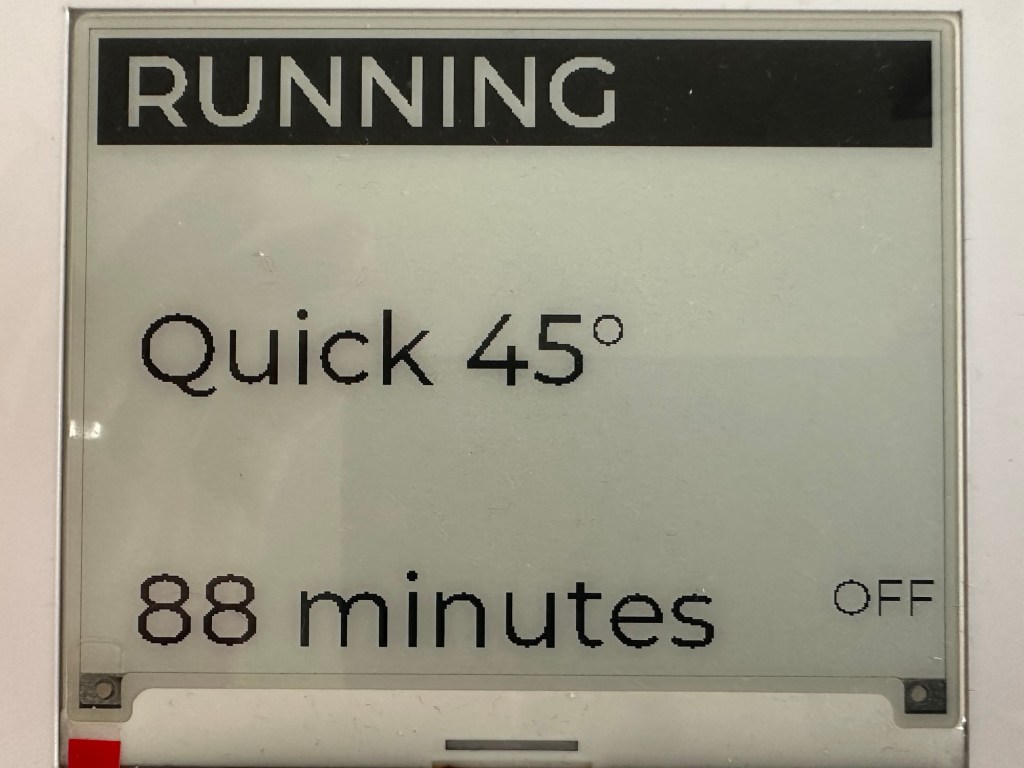

Porting my Tiny Matter Dishwasher to a CrowPanel E-Paper display

In this post, I look at how I ported my Matter ESP32 Dishwasher over to an CrowPanel e-paper display Read ⇢

-

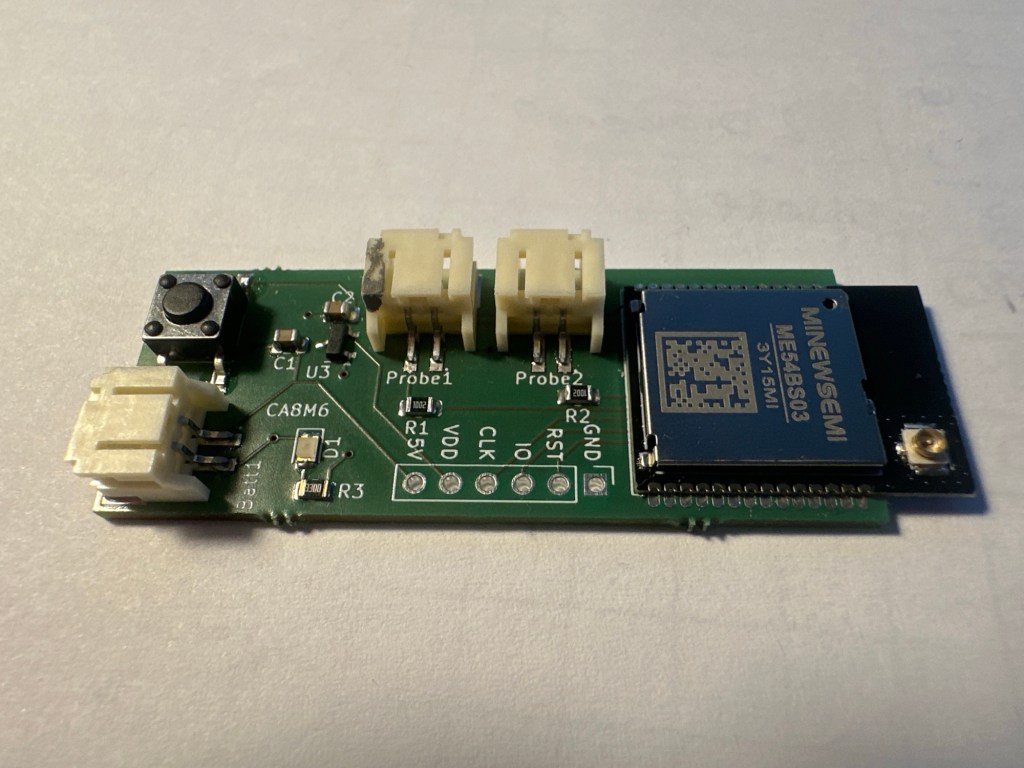

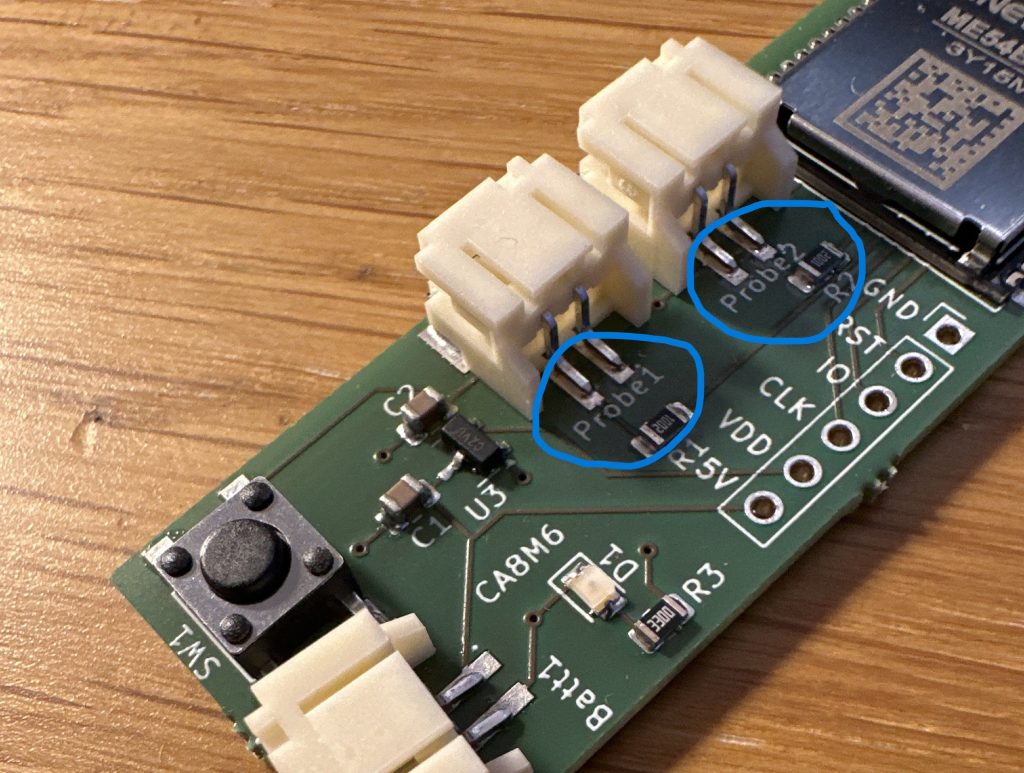

Matter Dual Temperature Sensor power consumption finally at 20µA!

In this post, I finally reduce the power consumption of my Matter Dual Temperature sensor down to 20µA. That will give me over a year on a single coin battery! Read ⇢

-

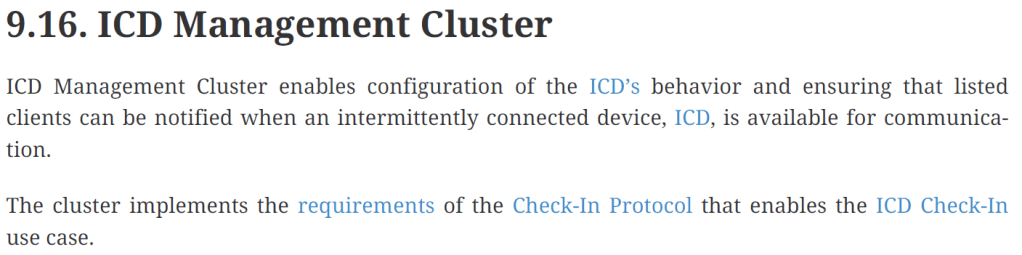

Dual Temperature Sensor – Support Matter ICD

In this post I finally finish some basic Intermittent Connected Device support in my Dual Temperature Sensor. I also work through some subscription issues. Read ⇢

-

Dual Temperature Sensor – Adding Power Source Cluster

In this post I look at the Matter Power Source Cluster and how I add wired and battery variations to my Dual Temperature Sensor Read ⇢

-

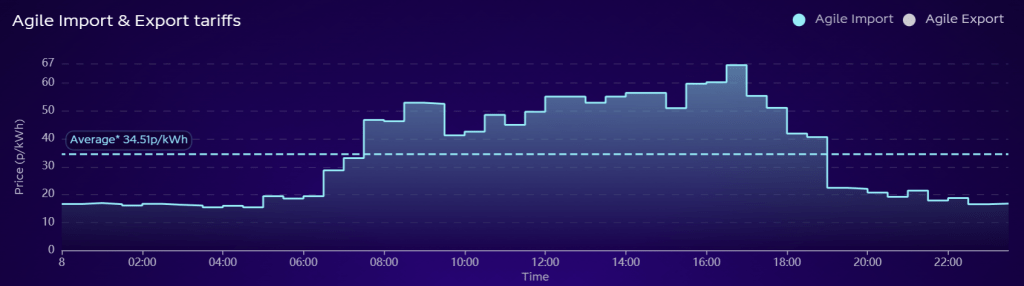

Exposing Octopus Agile prices through the new Matter Commodity Tariff Cluster

In this post, I expose Agile tariff information from Octopus energy via the new Matter Commodity Tariff Cluster. Read ⇢

-

Dual Temperature Sensor – Configuring FixedLabels in Matter

In this post I explore the FixedLabel and UserLabel clusters. I then add support for FixedLabels in my Matter Dual Temperature Sensor. Read ⇢

-

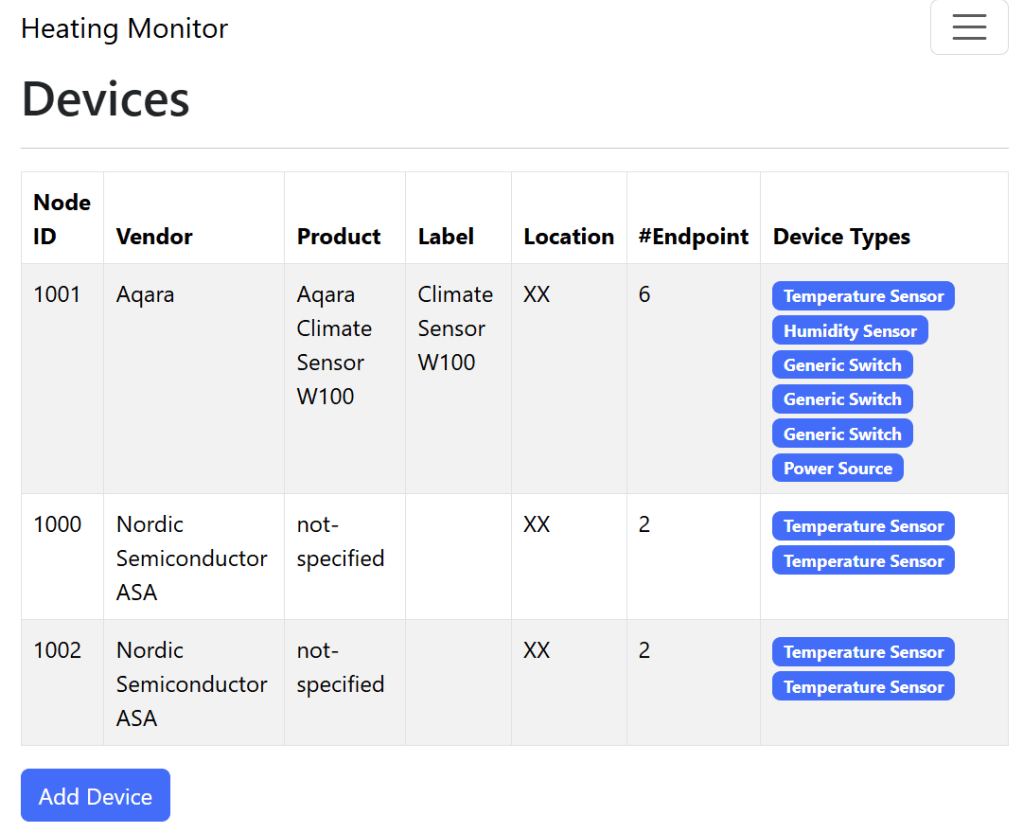

Matter Heating Monitor – Adding Subscriptions

In this post I look at some Matter subscription issues I encountered in my Heating Monitor Read ⇢

-

Matter Heating Monitor – Adding On-Network Nodes

In this post I look at how I added Existing Matter devices (OnNetwork) to my Heating Monitor Read ⇢