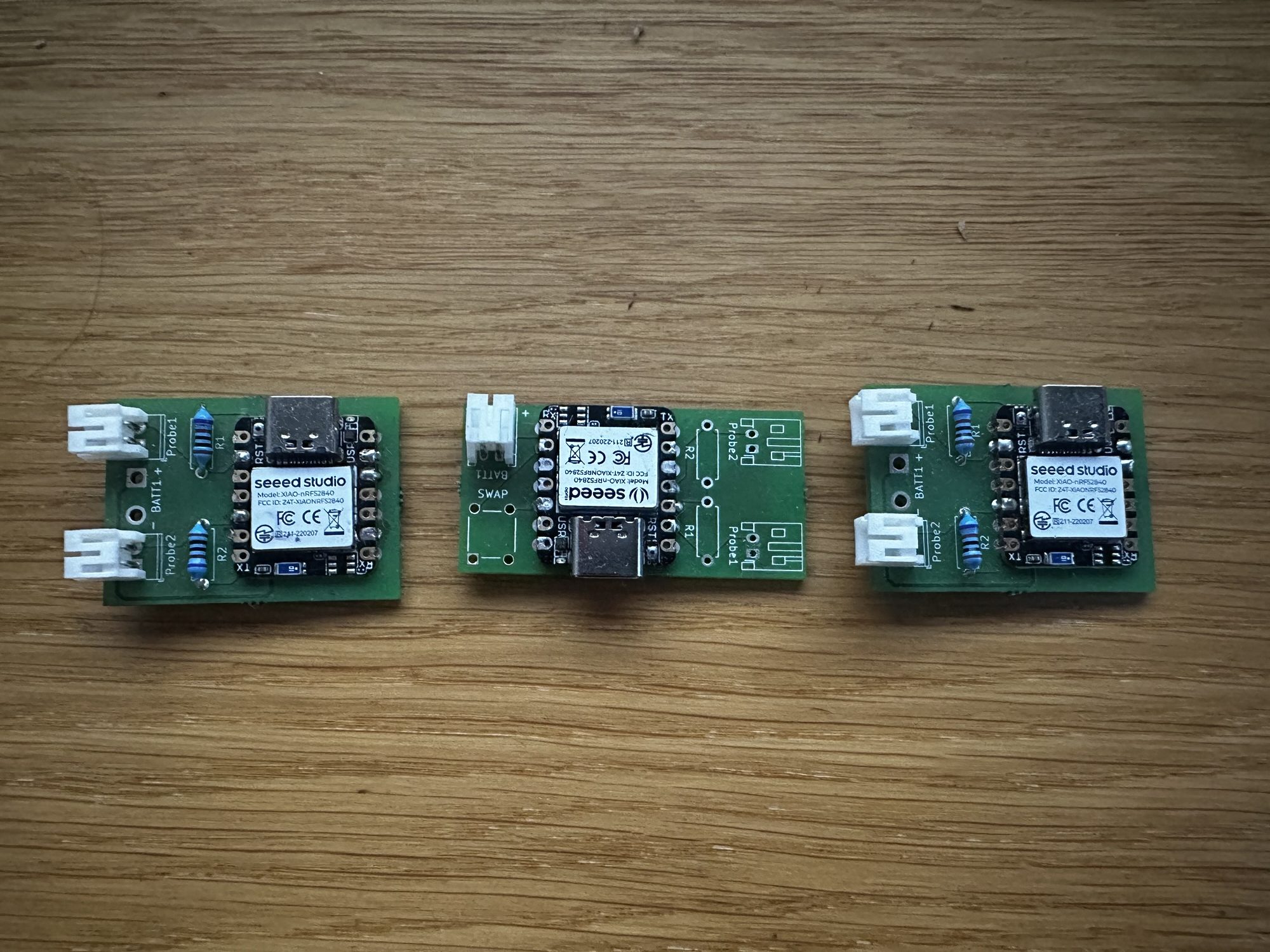

During the creation of my custom PCB, I made several mistakes in the design. With each mistake, I corrected the designed and tried again. It’s taken four iterations, but I arrived at a board that was basically fine.

This meant I had several XIAO boards soldered to the faulty PCBs that I really wanted back. At almost £10 a board, they aren’t cheap!

The problem I’m faced was is getting them off the PCBs!

I’ve tried and tried with a soldering iron, low temperature solder, copious quantities of flux. I managed to pry one off but had no success with the 7 others. They were held firmly in place.

What are the options?

I’m an amateur the electronics game, so I wanted to limit my budget. This ruled out most of the stuff that comes up first on Google.

Reflow ovens seem to be the best option as they can be quite large allowing large batches. Hot Air Soldering is another popular option. To get anything of quality, I’d be looking at over £200. For the amount of SMD work I was planning, this was too much of an outlay.

Other suggestions of Reddit ranged from using a clothes iron to putting stuff in the actual oven! All of these have drawbacks as they aren’t really suited to the task at hand.

After more googling, I found the category of product that I thought was suitable. Hot plate pre-heaters. These range in size and price and are typically designed for heating up PCBs before doing Hot Air soldering. They can, however, be used for small scale SMD work.

After a lot of searching, I found one that wasn’t crazy expensive but also wasn’t dirt cheap. When dealing with temperatures up around 300°C, I didn’t want something that would melt and/or explode.

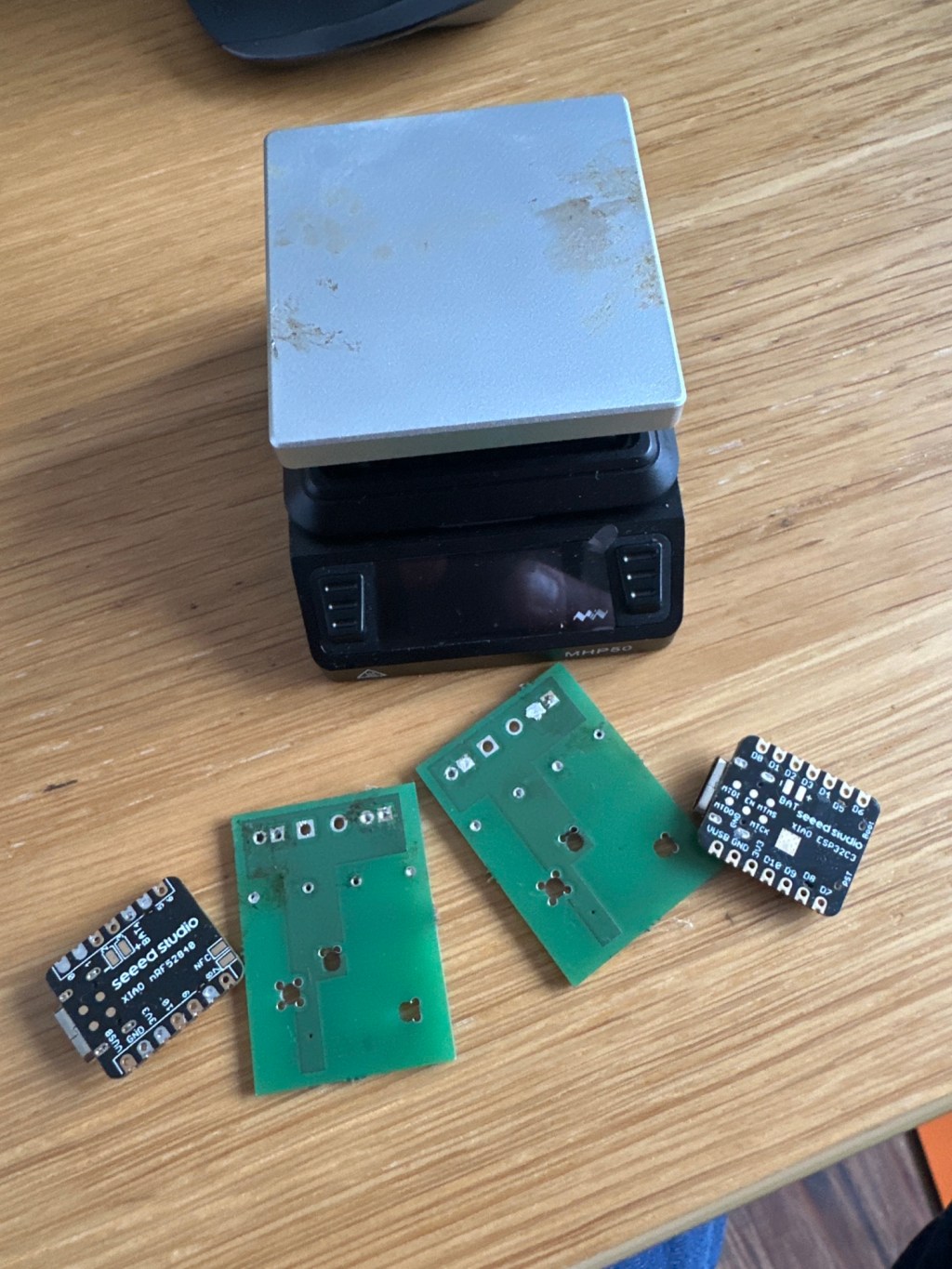

The unit I chose was the Miniware MHP50. This is a little USB powered hot plate. I picked up a second hand one on eBay for around £70 and it was in mint condition. It needs a USB supply capable of delivering high power. Thankfully, my laptop charger could deliver the required power.

First Attempt

I didn’t have a clue what I was doing, so I just set it to 350 and turned it on. I popped one of my original OSHPark (the purple is lovely) and left it on there for a few minutes. I expected to be able to lift the XIAO board off, but that wasn’t the case.

I forced it.

Big mistake.

Buy pulling the unit, I ripped copper pads off and everything. What a disaster.

Yikes.

Another go

I decided to be a little more cautious and I set the hot plate to 250. I then let the board sit for about two minutes, prodding it with tweezers until it moved.

This worked much better! The XIAO board simply lifted off using tweezers!

I then used some copper braid to suck up all the solder, as best I could. I then cleaned them with alcohol wipe to remove the flux.

As ever, it’s all a learning curve.

Next Steps

Next up, I’m going to try actually applying solder using this method. I’ve ordered some solder paste and I’ll see if I can mount the board using that.

My biggest challenge with this PCB and the XIAO, is that the battery terminals are on the rear of the board. As a novice, this is proving to be a problem. I’m hoping that I solder paste will help in this situation too.

Leave a comment