In my last video, I poke a little fun at my oversized boiler before diving into the importance of sizing your boiler correctly!

Author Archives: Tomas McGuinness

High CO2 Levels at Home

In this video, I discuss the discovery of high CO2 levels in my house at night and how I’m wondering if they are impacting our sleep quality.

Installing a Home Assistant Control Panel in my kitchen

Some lessons learned from a new heating system

If you’re planning to upgrade your boiler or heating system, I would like you to read this post. I learned some valuable lessons since having a new heating systems installed in March 2021. I want to tell you what those lessons were. They might help you get better performance our of your new system!

New everything in our new house.

In 2021 I relocated from London to Solihull. We bought a house in need of renovation and during the first few months of that year we had the plumbing, electrics and some structural works carried out.

At the time, I knew nothing about plumbing, heating, boilers etc. We were giving a strong recommendation of a plumber and got them around to give us a quote.

I had heard about heat pumps and wanted to see if one of those was an option. When I first broached the idea, it was dismissed out of hand as my property was too old and unsuitable. We were on a tight deadline to get the renovations completed, so we agreed on a gas boiler. I knew that big radiators and big pipes were important to have with heat pumps, so I pushed to have larger than usual radiators installed.

We discussed a future extension and underfloor heating and the plumber recommended a 30kW system boiler. I nodded in agreement as I’d no idea if that was big or small. Trust the professional.

They did the installation. The work was very tidy, completed on time and budget and we were very happy.

First Winter and our first eye-watering bill

Fast forward six months. Winter had arrived and the heating was turned on. Towards the end of November, we had a cold snap and in one single day, the 28th of the month, we used about 200kWh of gas.

I had no clue if this was a lot of gas. It certainly seemed like a lot. I posted my question to Twitter and quickly got confirmation that it was an insane figure for a standard four bedroom house.

I checked my usage against friends and family and it became obvious to me that we were simply burning more gas than everyone else.

Down the rabbit hole

Given that I wasn’t happy burning gas in the first place, burning more than I needed was adding insult to injury. I set about trying to understand why our usage was so high.

The first thing about was how modern boilers have a condensing mode.

Condensing Mode

You’ll most likely have heard the term condensing boiler. I, for one, hadn’t a clue what that actually meant 🙂

As I now understand it, condensing is a way the boiler recovers heat from the flue (exhaust) of the boiler. It takes some of the heat that would otherwise be blown out the flue and puts it back into the water. It has a pretty dramatic impact on your boiler’s efficiency too; when it’s not condensing, efficiency might only be about 80% and when it’s condensing it will be up in the 90s. My boiler has a 93% efficiency.

So what’s the catch? Well, as I discovered, your boiler only works in condensing mode in certain circumstances. To help explain this further, I need to introduce two more terms; flow temperature and return temperature.

Flow Temperature: What is it?

Flow temperature is the temperature of water coming out of your boiler. It has nothing to do with your thermostat or anything like that. When your boiler is running, it will try and keep the water in your pipes at the flow temperature.

Return Temperature

If flow temperature is how hot the water leaving your boiler is, return temperature is how hot the water coming back to your boiler is.

As the water flows around your radiators, the heat in the water is released in your house. The boiler then heats this water up again and this happens around and around.

What does this have to do with my boiler’s condensing mode?

Everything, really. I don’t know exactly how all this works, but I know that a boiler will only operate in condensing mode when the return temperature is below 55 degrees Celsius.

This is really important to note because most boilers are installed to have a flow temperature of 70 and a return temperature of 50. You might think that this means your boiler is in condensing mode all the time, right? Unfortunately, you’d be wrong. The 70/50 rule is used to ensure your heating system is putting enough heat into your house when it’s freezing outside. But what happens to your return temperature when it’s, say, 7 degrees outside? Well, the return temperature goes up.

When it’s warmer outside, your house doesn’t lose heat as quickly. This means the water in your radiators don’t put as much heat into your house, so the water coming back to your boiler is warmer. When the temperature of the water returning to the boiler is warmer than 55, the boiler will stop condensing.

What can I do?

You can turn down the flow temperature of your boiler. If you drop this down to 55, for example, you can almost guarantee that the return temp will be lower, and the boiler will condense. You will also burn less gas since the boiler isn’t heating the water as hot.

That sounds great.

If you have a combi boiler, you can do this straight away! If your house ends up being cold, you can always turn the flow temperature back up! If you want to read more, I recommend this article from the heating hub: https://www.theheatinghub.co.uk/articles/turn-down-the-boiler-flow-temperature

If, like me however, you have a water cylinder for your hot water, things get a little more difficult!

After I learned about condensing modes and flow/return temperatures, I immediately dropped my boiler’s flow temperature down to 55. Almost immediately, I did see my gas usage drop whilst the house stayed warm.

My initial happiness was short-lived after wife complained about the lack of hot water one morning. She will tolerate a lot of my smart home shenanigans, but messing with the hot water is a no-no!

What was the problem?

System Boilers, like mine, typically have only one flow temperature. When I lowered the flow temperature to 55, it reduced the gas I burned, but it made it impossible for the boiler to heat the water in my tank to 60!! I hadn’t really understood that as a side effect.

I was really confused because in my previous house, I could set *two* temperatures on my boiler. One for heating and one for hot water. Billy, my plumber, had explained this to me, but as this happened in 2017 I knew even less about heating and was completely uninterested. Billy was, as I would come to realise, ahead of his time!

Fast forward to 2021 and the penny dropped. I wouldn’t be able to run a lower flow temperature. Not only would it result in a lack of hot water, but there were also other considerations, such as legionella, which I won’t go into. If you want to know more, read this amazing article by Heat Geek on legionella.

Given my Viessmann boiler in my old house let me have two temperatures, I couldn’t understand why my Worcester Bosch boiler didn’t. The boiler had both hot water and radiator buttons on the front, but the hot water icon was disabled.

I knew I needed to lower the flow temperature for the heating, but I also needed a higher flow temperature for my hot water. I put my boiler question to Twitter and, sure enough, received enlightenment!

Priority Domestic Hot Water

Priority Domestic Hot Water is what I was told. I had to google this. I learned it’s the industry name for a setup that allowed a boiler to have different flow temperatures when heating your house or heating your hot water. It will also ensure that your hot water needs come before your heating needs. That’s the Priority in PDHW. Exactly what I needed! Knowing the “technical” term, I started googling!

I soon discovered that the reason my boiler’s hot water symbol was disabled was because it required the installation of an “internal diverter value”. Without it, the boiler can’t enable the dual temperature function.

To install the Diverter Valve, however, required not only the the installation of the valve, but the alteration of the pipework! I rang around a few Worcester Bosch installers and found one (out of three I spoke to) that a) knew what I was talking about and b) was willing to do it. The cost: £400 and he couldn’t do it until February at the earliest.

Pseudo priority domestic hot water

As I needed a more immediate solution, I started looking for a digital solution. I’m a programmer, so my view is that you can solve everything with software 🙂

I had already found an open-source project online called ESP-EMS and, with a small piece of hardware purchased in the Netherlands, was happily monitoring my boiler’s behaviour.

I realised that I could use this to adjust the flow temperature of my boiler using Home Assistant. Using a Shelly i3 to monitor the call for hot water, I created an automation NodeRed that would just adjust the boiler’s flow temperature automatically. When my Mixergy tank needed heat, the EMS-ESP would increase the flow temperature to 70 and when it didn’t, the flow temperature would drop back to 45. (If anyone is interested in how I achieved this, drop me a note in the comments)

Whilst posting about on Twitter about how proud I was of my digital solution many months earlier this year, Richard Burrows of MWPHS pointed out an even simpler solution which involved a 10kOhm resistor.

Richard also shared this video with me, where he walks through how he converting a Worcester Bosch to PDHW without any plumbing changes.

I had to try it out the 10k resistor suggestion and I made a recording of it! You can watch how I became lost for words:

How has it worked so far?

I first installed the EMS-ESP board in November 2021 and implemented my homemade flow control in February 2022. I added the resistor in March 2023. Between both of these, I’ve been running dual flow temperatures for about 18 months, and it never failed.

It’s not perfect, don’t get me wrong. Its main drawback is that I’m missing the “priority” part. If the heating is on and the Mixergy tank needs to heat water, the 70 degree flow is used for the heating and the hot water. This is bad in two ways; it takes much longer to heat the water and the radiators are hotter than I need them to be, wasting gas. The same happens if the boiler is heating water and the heating kicks in.

As Richard mentions in his video, he needed to add relay control so the boiler only sends the 70 degree water to the tank and not the radiators. This I something intent to change in my system later this year as part of my project to move all heating control to Home Assistant. (I’ll document that here and on YouTube, so be sure and subscribe)

Weather Compensation

Once you can change the flow temperatures independently, you can take advantage of another piece of boiler wizardry: Weather compensation. This is the simple idea of changing your radiator temperatures based on the weather outside. When it’s subzero, you want loads of heat. When it’s 12 outside, you don’t need as much.

Boiler Sizing

Another aspect of gas boilers, which directly impacts your bills, is their size. I mention earlier in this post that my plumber recommended a 30kW boiler. I don’t know how he arrived at this figure, but I’ve learned that it’s WAY TOO BIG! It’s at least twice as big as it really needs to be!!! I will write up another post on this as it’s a very important topic.

Final thoughts

If I had known about these things back in 2021 I would certainly have pushed to have them incorporated into my system. They would have been worth the money.

I’ve got another post worth of thoughts on Smart Thermostats, related to weather compensation and smart TRVs, which I will post at some point in the future.

If you’re having a new system boiler installed, please, please, please speak to your plumber/engineer about priority domestic hot water and weather compensation. They should be able to advise you on what would work best (better than me anyway!)

Your wallet, and the planet, will thank you!

A quick look at the Android tablet I’m going to use with Home Assistant

In my latest YouTube video, I unbox an Android powered point-of-sale screen that I’m planning to use as a Home Assistant control panel.

I’ve been running Home Assistant for a few years now, but something I always wanted to add was a control panel.

This was always going to be an iPad or Android tablet. I even went as far as buying a ethernet to lightening adapter, so I could get internet and power to an iPad. However, I was never 100% comfortable with the idea of a battery powered device being plugged in all the time.

At the start of the year, I came across Android powered displays. These are typically used in restaurants and kitchens to provide incoming orders from apps like Deliveroo.

They are designed to operate almost nonstop, have no battery and, best of all, have PoE (Power over Ethernet) built it.

Once I knew what to search for, I found lots of people were using them as control panels! Bingo.

I wanted to buy one from a company in the UK, rather than have one shipped from China (economics and CO2) After lots of looking, I found https://www.goeducation.co.uk who sell all kinds of digital signage. The have a few different offerings, but I settled on their 15″ POS display. https://www.goeducation.co.uk/15-POS-Android-Advertising-Display-p/dgs-pos-aad-pos15hd7b.htm

It was more than I’d planned to spend, but as it had everything I wanted, I purchased one.

Here are some of my initial thoughts on the device itself:

- It’s thicker than I expected.

- The display is clear and bright.

- It’s PoE, so won’t require a power brick. Power consumption is about 20W, so it won’t cost the earth to keep running.

- It’s running Android, so I’ll have access to Kiosk style apps and screensaver functionality.

- It has colour changing bars along the side, which I’m going to try and take advantage of. Red for something needs attention, green for everything is okay.

- It’s only running Android 8, which isn’t great since it no longer gets security updates.

I haven’t installed it yet, but I have a spot available on my kitchen wall, where I’ve had an Ethernet cable installed just for a control panel.

As the device is about 1″ thick and keeping my wife in mind, I’m going to have to recess the device into the wall. Thankfully, it’s dot and dab plasterboard on blocks, so by cutting out a rectangle of plasterboard, I’ll have a deep recess for it. I’ll mount it to the block wall and then probably build a small frame to hide the exposed plasterboard.

I will do another YouTube video when I’m installing it, so if you’re interested, be sure to subscribe to my YouTube channel or bookmark this post.

Wrong ribbon?

My plan to use the Eddi relay board to interface it with my Mixergy tank has had its first setback. The ribbon cable is the wrong size!!

I’m waiting on a replacement from Myenergi!

Solar PV and the Eddi. Should I heat all the water??

My Eddi has been installed for about two months now. It has been a great addition to my setup quietly mopping up mountains of surplus PV and heating hot water.

I installed it myself and documented it over on my YouTube channel, so if you’re interested in that, check it out:

But it hasn’t all been roses!

The first very sunny day after I installed it saw the temperature of the water in my Mixergy tank hit 80 degrees Celsius!!! With small children in my house, it’s downright dangerous!

“At 60°C, it takes one second for hot water to cause third-degree burns.”

https://www.betterhealth.vic.gov.au/health/conditionsandtreatments/burns-and-scalds-children

Once I was made aware of the problem, I reached out to Mixergy and they explained how to limit the temperature using the safety cut-off of the heating element. I’ve made a video showing how I went about it, and you can watch that here – https://youtu.be/tIxomiHLhI0

To go off topic a little, another solution to this dangerously hot water is the installation of a thermostatic mixing valve. These are the same type of valve that control the temperature of the water coming out of your shower (assume it’s not electric!). It will blend the water coming out of the tank with cold water to ensure it’s at a set temperature (45 or 50). If you had solar thermal for example, this would be an absolute must!

I digress.

Having initially dropped the maximum temperature down, I started to wonder. Having a higher cut-off temperature would mean I could divert more solar into the tank. This would increase the amount of solar PV I “consumed”, which I’m always reading is better than exporting.

Is diverting all the surplus the right approach?

In order to understand more about the Eddi and Mixergy’s behaviour, I pushed the cut-off temperature back up to 75. This would give me an idea of how it worked when I was diverting *all* the surplus into the tank.

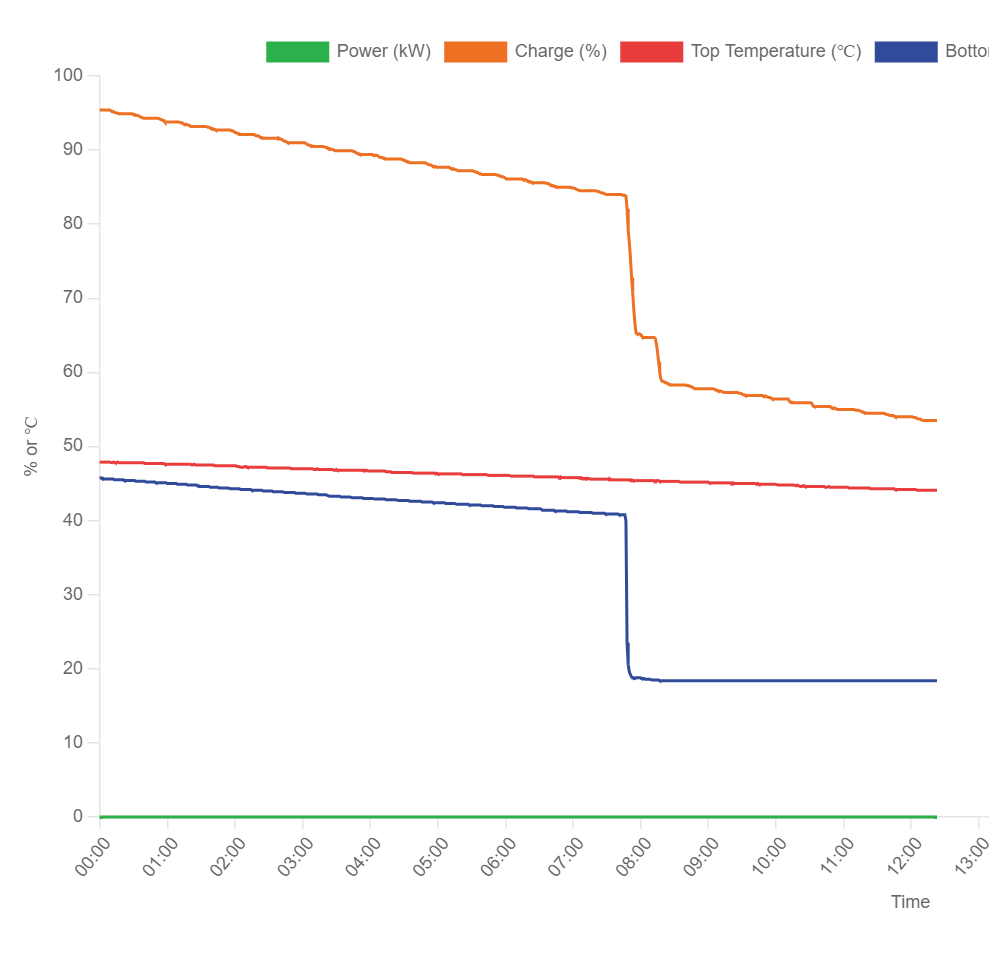

This is an example of my tank’s behaviour on a good sunny day:

You can see around 11:30 the orange line starts going up. This is the percentage charge. Mixergy works this percentage using the temperature gradient across the tank and compares it to the desired water temperature. My desired water temp is 50 degrees. As the top and bottom of the tank hit around 50 after an hour or so, the charge reaches 100%.

As the sun was still shining, the Eddi kept diverting. Note the red line. This is the water temperature at the top of the tank. This continues to rise to around 75 at which point the element’s cut-off kicks in and the Eddi stops diverting. For the rest of the afternoon, it turns on and off a dozen times as the tank’s water naturally loses heat. As the temperature is still well above 50, the tank registers 100% charge.

It’s not until 10pm that we see something happen. The temperature suddenly drops. I’m not sure why this isn’t a nice gradient, but that doesn’t matter. You’ll see the percentage charge starts to drop as the water cools.

This cooling continues into the next day, hitting 83% before the first shower. It’s interesting to note the bottom temperature drops like a stone as cold water comes into the bottom of the tank.

We haven’t had to heat any water this morning as there was enough in the tank to cover two showers.

However, we’ve pumped in several kWh of electricity, only to lose it overnight in the form of heat loss. That seems wasteful. Not only is 75 degree water dangerous, it’s also kinda pointless. We’re not paid a great deal for exported energy (4p per kWh), but it’s better than heating the air in the garage.

Is there a better balance?

I think there is a better balance to be found. I want to combine the percentage charge data I get from the Mixergy with the Eddi, so that the Eddi will stop diverting once the Mixergy reports 100% charge. This will mean we’re not constantly diverting and having a lower temperature in the tank will also slow the rate of heat loss.

How?

For my smart home, I use Home Assistant. I have written a plug-in that let’s me access the information from my Mixergy tank. So that’s one piece of the puzzle in place.

For the Eddi, it’s a little more involved. Myenergi do offer an API for their Eddi, but the control is limited to On/Off. For my needs, I want to be able to tell the Eddi to pause diverting. Fortunately, the Eddi has an add-on board which does just that!

When I purchased my Eddi, I added the relay board to my order as I had visions of heating my bathroom’s dual-fuel radiator.

The plan is this: Install the relay board into the Eddi and configure it so that it’s linked to the immersion element. Home Assistant will then trigger a relay when the Mixergy reports 100% change, which will tell the Eddi to stop diverting. When the charge drops below 100%, Home Assistant will trigger the relay again, causing the Eddi to resume diverting!

If this automation fails for any reason, the hardwired cut-off will still be present to stop the water getting too hot.

I’ll document this and do another blog post & video with the results.

First sunny month with new solar PV

With June being the first really sunny month of the year, I wanted to share my thoughts on how well my newly installed Solar PV setup performed.

Setup

I have two arrays on my house, consisting of eight plans on the main roof of the house, south facing and a smaller four panel array on my extension, facing the same direction. Lots of shading occurs due to neighbour’s chimneys, the house itself and the forest at the bottom of the garden. I have a 3.6kW inverter and a 5.8kWh battery (90% DoD). We have a Zappi charger for our EV and use an Eddi for hot water boosting.

Generation figures

I use Home Assistant to log more stuff, so here is the total energy distribution for June 2023.

My panels generated a total of 634kWh of electricity for the month. The month was mostly sunny with the odd cloudy days during the month.

Best saw 30.33kWh generated and worst day only 7.23kWh generated.

During the month I manged to exported almost 80kWh and imported 113kWh from the grid.

Summary

I’m pretty happy with the figures but I won’t have the full picture until I get the bill from Octopus, which will show how much of that 113kWh was split between peak and off-peak.

If I could consume every bit of electricity generated by the panels, they would have met our entire electrical demand for the month. However, this would require additional battery storage and a little more pro-activeness on our side to turn things on etc. to take advantage of the surplus.

Predicting periods of excess solar power

My solar PV has been in and working now for several months. We’ve tried to adjust our usage patterns to take advantage of when there will be excess solar after our battery and hot water tank are filled.

This has been something I’ve been thinking about for a while and I have a few ideas.

I have no shortage of data, so I’ll need to first figure out the prediction process. This can probably be done with a simple machine learning tool and the data from my smart meter combined with the solar forecast. If I have can compare these values across multiple days, I think a system could predict based on a time period we’d experience our first export.

The other side is surfacing that data. That’s the bit I know how to do. Perhaps a simple eInk display beside the washing machine that reads something like “Put me on around 3:30pm” or similar.

I’m gonna dig into this as and when I can and I’ll document my findings here.

Wiring for smart lighting with Shelly relays!

I’m building an extension to my kitchen.

As readers of my blog and Twitter will know, I love home automation and building work presents an opportunity to incorporate more of it!

My Current Smart Lighting

The vast majority of smart lighting in my house is provided by Shelly devices. These are incorporated into the ceiling roses or loft spaces and provide 99% of the lighting control. When my house was being refurbished back in 2021, I asked the electrician to ensure that each ceiling rose had a permanent live or that the permanent life was easily accessible. This enabled me to add the Shelly 1 devices without any drama.

A different approach

With our new extension, we were going to have a mix of down lights, track lights and pendants. The track lights and down lights would make the Shelly 1 devices really tricky to install. I had a chat with my electrian and asked him whether or not I could have all the wiring pulled back into one central location. I explained how the Shelly devices worked and he said it would be no problem at all.

To explain this a little better, I’ll go over how it’s “typically” done.

In a typical ceiling rose, power from the consumer unit (fuse board) arrives at the unit. A wire then runs from the pendant down to the switch. Power is sent down to the switch and comes back to power the light.

In my arrangement, the power, lamp wire and switch wire would all be come back to a single location, where I could install a Shelly device.

I had eight lighting circuits in total, covering the kitchen, the utility room and the outside lighting. After first fix of the electrics (where all the wires are put in) we had a mass of cables!

Wiring it all up

The electrician decided to use a small consumer unit to store all the wiring which was a great idea. It provided common rails for the multiple live and neutral wires what would be needed.

After a little troubleshooting, he got it all wired in.

When it came to configuring the Shelly devices, I hit a few bumps. Firstly, two of the little buggers were dead. I knew I’d fried one or two of my original ones when I was first installing them (one electrically and one botched firmware install), but I never threw them out. This meant I only had six operational units. The sixth one worked, but I couldn’t connect it to the Wi-Fi network, so it was practically useless. I scavenged a dimmer module from another light so the electrician could finish.

It was when I came to adding everything in Home Assistant that the biggest problem revealed itself. The metal consumer unit wreaked havoc with the Shellys’ Wi-Fi connection. The RSSI was really poor, and my experimenting showed about a 30% success rate when trying to operate the light via the app. They don’t have any external antenna, so I knew they’d always struggle.

Going Pro

At this point, I recalled that the Shelly product line contained the perfect alternative. The Shelly Pro range! These are DIN rail mounted units, designed specifically for consumer units. They provide the standard switch wire and on/off support, but also have power monitoring included.

More importantly, they also have ethernet connectivity, which would solve the problems caused by the big metal box. Unfortunately, I didn’t have any ethernet cables going to the unit, so that would have to be solved first.

Moar ethernet!

After some detective work in the eaves and loft, I found a route for my ethernet cables that didn’t involve any drilling or fishing of cables. I pulled in two cables and fished them down through the kitchen ceiling into the unit where the consumer unit was installed. All invisible, no orange wires showing, which is important.

I have isolated the wiring unit at the fuse board and checked with my Fluke tested before I started feeding cables in. If you are working with electricity, please be careful! If you don’t know what you’re doing, get a professional!!

With some help from my wife and a coat hanger, we got the two ethernet cables through.

I have lots of ethernet cables in the loft, along with a small five port switch. I crimped the cables and tested them. Stage one complete!

Stage two was replacing the Shelly units. I worked one by one until, removing the wires from each individual Shelly and moving them into the Shelly Pro. I did it slowly like this as nothing was labelled, so this way I didn’t have to keep track of too much. The switch wires were either different colours or had a little collar on them.

After about an hour, I was finished. I connected the ethernet cables and both devices appeared on my network. I did a video of the whole process and it’s up on YouTube – https://www.youtube.com/watch?v=hxtuzFlFZ5s

Improvements!

So aside from the issues with WiFi and a metal box, the approach worked out as planned. That said, one thing I’d have benefited from was an isolation switch. When I was swapping out the Shelly 1 devices for the Shelly 4 devices, I had to kill the power at the fuse board, which is in the garage. A couple of trips back and forth could have been saved by having a switch beside the unit.

Next step is to add these to my Home Assistant integration and connect them to Homekit.